MSAI Connect for Motors - Monitoring & Performance Optimization

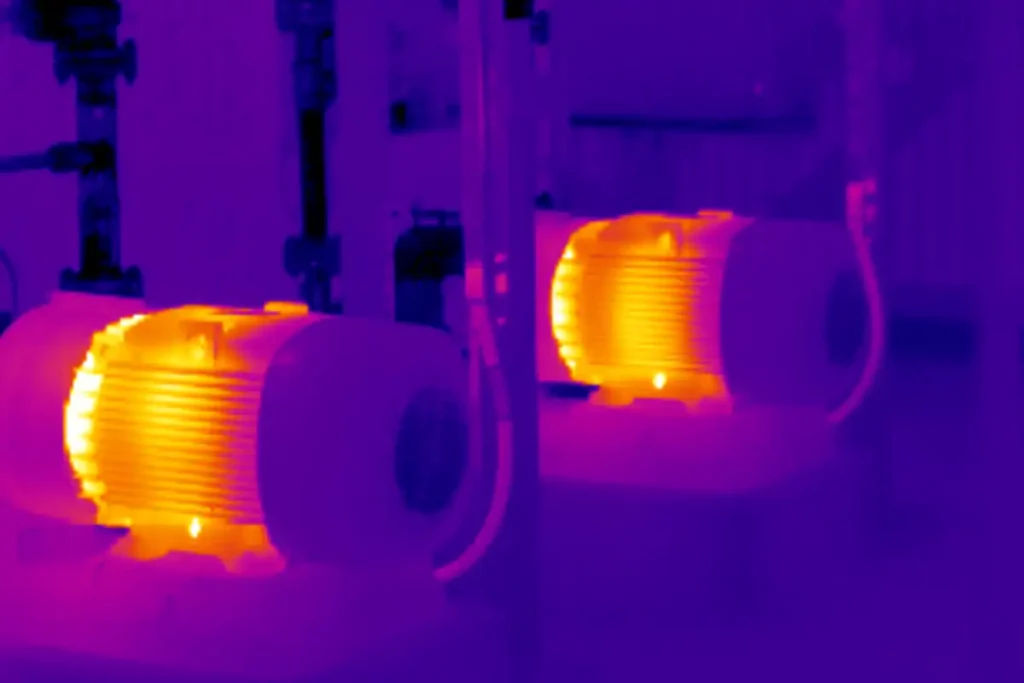

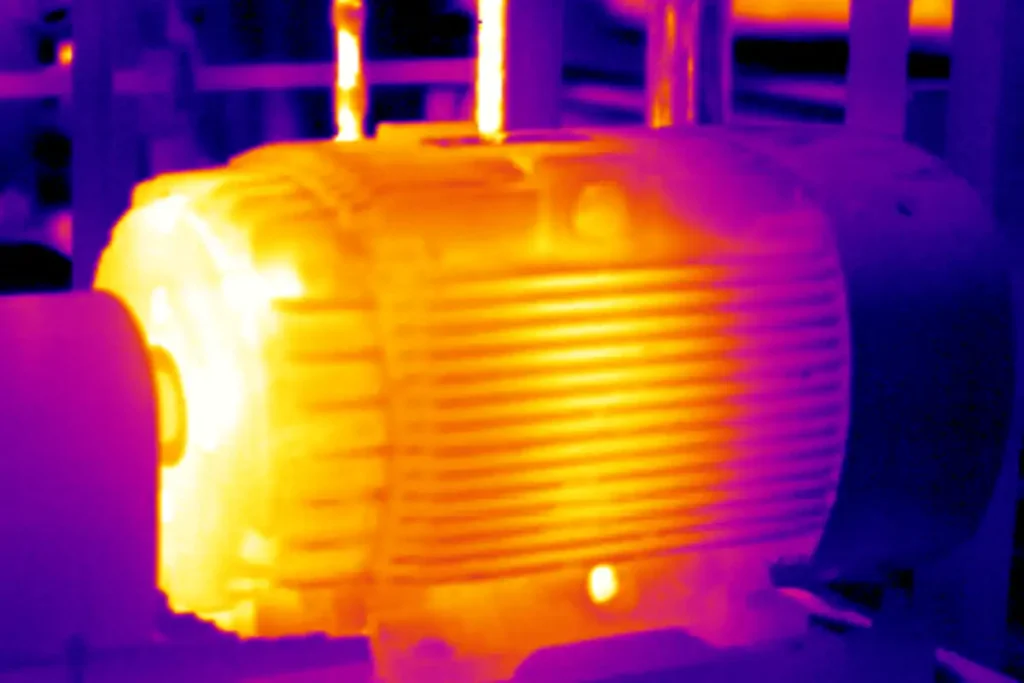

Improve motors reliability and performance with ICI’s MSAI Connect platform. Detect early warning signs, prevent failures, and optimize efficiency with real-time thermal monitoring.

Why Choose Us

Enhancing Motors Lifespan and Reliability

Motors are critical to powering industrial equipment, automation, and material handling. MSAI Connect’s predictive analytics and AI-driven insights enable businesses to detect potential failures early, improving operational efficiency and safety.

Applications for Motors

Why Choose MSAI Connect for Motor Monitoring?

MSAI Connect leverages AI-powered thermal imaging to identify motor issues such as overheating, imbalanced loads, and faulty insulation, preventing costly breakdowns and downtime.

-

AI-Powered Motor Health Monitoring

MSAI Connect analyzes thousands of real-time data points to detect overheating, ventilation issues, and electrical faults before they lead to failure.

-

Automated Alerts & Predictive Maintenance

Receive instant notifications for temperature spikes, lubrication issues, and insulation degradation, allowing for proactive maintenance.

-

Seamless Integration into Operational Systems

MSAI Connect easily integrates into existing workflows to automate maintenance schedules and improve reliability.

-

Reduced Downtime & Increased Efficiency

Prevent motor failures, extend lifespan, and enhance productivity with data-driven decision-making.

Where Can You Use MSAI Connct for Motor Monitoring?

Optimizing Motor Performance Across Industries

MSAI Connect enhances motor efficiency and reliability in key industrial sectors.

Manufacturing

Electric Utilities

Oil & Gas

Intelligent Condition Monitoring for Motors

Predict & Prevent Failures with MSAI Connect

MSAI Connect's real-time thermal monitoring system detects potential motor issues before they escalate, allowing businesses to optimize performance, prevent failures, and reduce costs. Contact us today to schedule a demo.