Electrical Inspections with Infrared

Why Choose Us

Proactive Electrical Maintenance with Infrared Technology

A small electrical problem can quickly turn into a system-wide shutdown. Until your team finds and replaces the faulty equipment, production comes to a halt. Infrared electrical inspections can help ensure an operation never reaches that point. By finding damaged components early, infrared energy audits allow you to plan for repairs and prevent downtime. They are essential to maintaining a productive business and an efficient electrical system. ICI provides unbeatable, highly accurate electrical inspection solutions. Our infrared systems quickly detect high temperatures, which are an early sign of failing equipment or fire hazard. Inspect your entire electric power distribution system and see what the eye would normally miss. From facility monitoring to new home inspections, ICI’s solutions keep things safe and moving forward.

Electrical

Why Choose Infrared Cameras for Electrical Inspections?

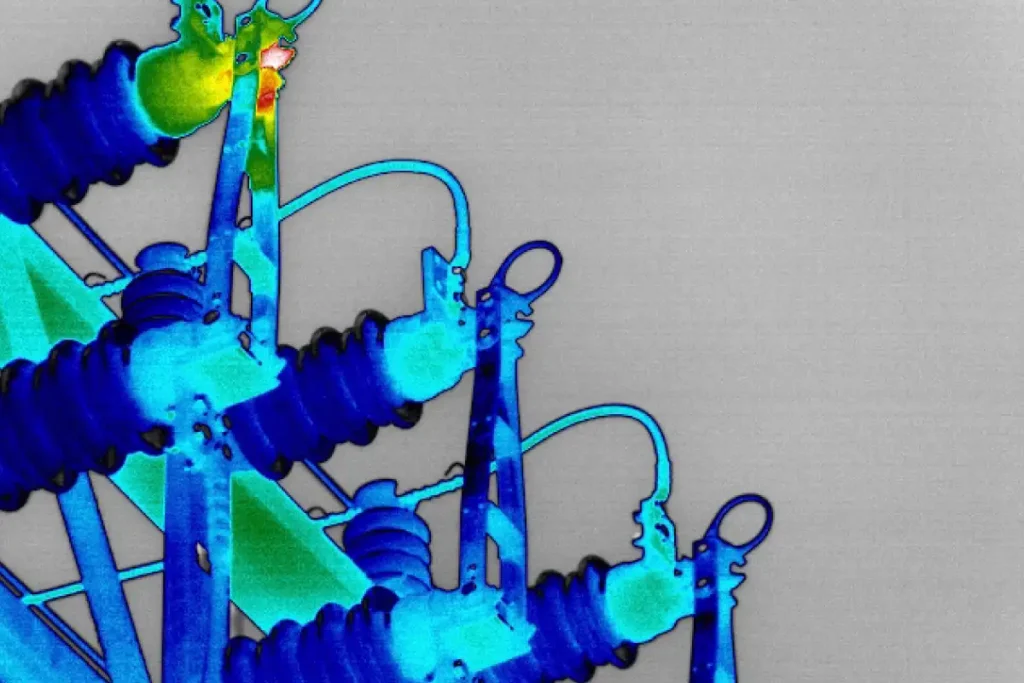

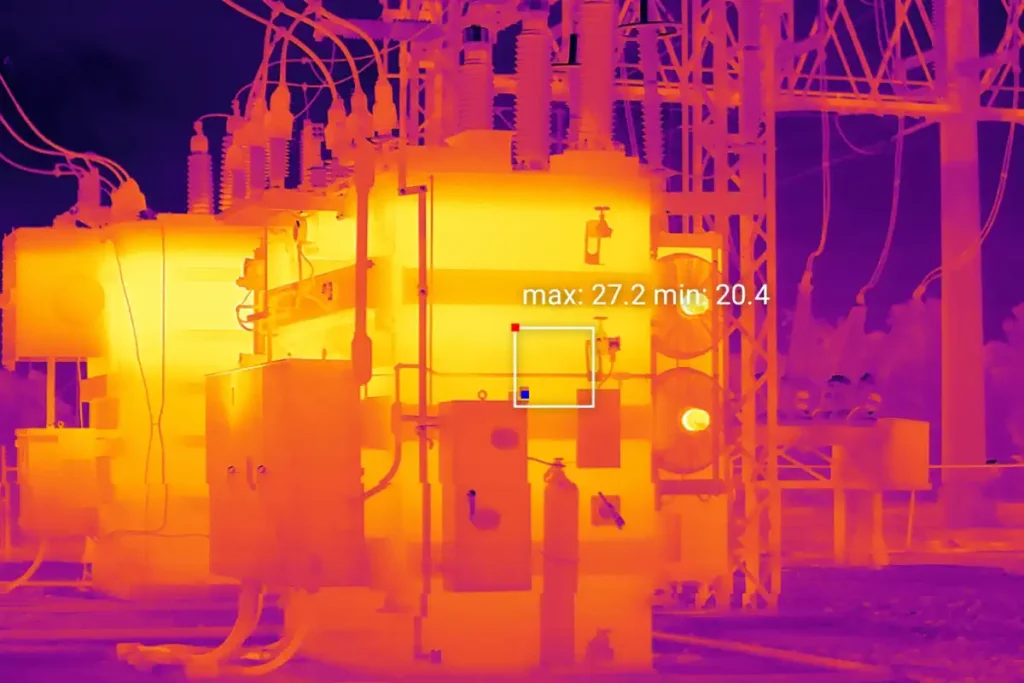

Electrical thermal scanning uses an infrared camera to create a high-resolution temperature map. In an infrared electrical inspection, this image identifies hot spots and helps you catch issues early on. You can identify hazardous equipment before it fails, before it melts, or corrodes other components.

Infrared is useful for checking switchboards, electrical cabinets, insulation, transformers, connectors, and more. Find overloaded equipment, corrosion, loose connections, and damage or deterioration of all kinds. Plan ahead and keep business moving with infrared energy audits.

-

Early Detection of Electrical Hot Spots

Detect overheating components to prevent system failures, downtime, and potential fire hazards.

-

Efficient Electrical Energy Audits

Perform energy audits to identify inefficiencies and optimize your electrical system's performance.

-

Preemptive Fault Detection

Detect electrical faults before they cause system failures, ensuring consistent energy flow.

-

Comprehensive Energy Audits

Perform detailed energy audits to optimize electrical systems and reduce energy wastage.

Boost Electrical System Reliability

Electrical Applications

Industrial Buildings

Commercial Buildings

Residential Housing

Preventative Electrical Maintenance

Infrared Inspections for Electrical Systems