SmartIR Manufacturing & Software for Asset Reliability and Performance Monitoring

Improve asset reliability, minimize downtime, and enhance safety with MSAI Connect's AI-powered thermal imaging solutions for manufacturing facilities.

Why Choose Us

Thermal Technology in Manufacturing

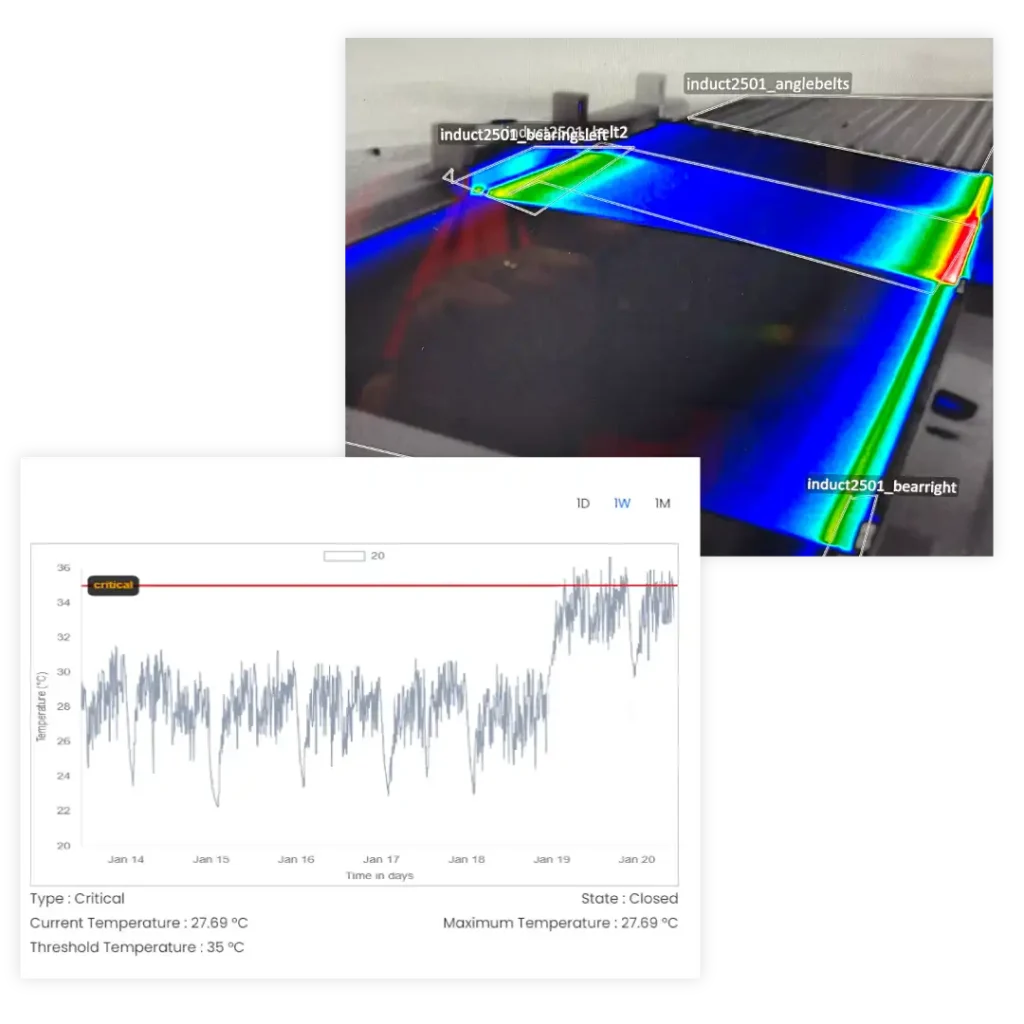

Thermal imaging is revolutionizing modern manufacturing by enabling real-time monitoring of critical assets. MSAI Connect leverages AI-powered algorithms to detect overheating, mechanical stress, and abnormal energy consumption before issues arise.

Intelligent Condition Monitoring for Critical Assets in Manufacturing

Why Choose MSAI Connect for Manufacturing?

MSAI Connect provides continuous condition monitoring for motors, bearings, gearboxes, ovens, and more. With real-time alerts for anomalies, MSAI Connect ensures optimal asset performance while reducing downtime and safety risks.

-

Optimize Predictive Maintenance & Reliability

MSAI Connect enhances predictive maintenance with AI-driven insights, allowing for proactive repairs and reducing unplanned failures.

-

Avoid Operational Downtime & Wage Stagnation

Prevent costly shutdowns by identifying mechanical issues early and ensuring consistent productivity.

-

Maximize Asset Lifespan & Reduce Costs

Extend the life of motors, conveyor belts, and critical power systems while minimizing repair and replacement expenses.

-

Improve Safety & Prevent Facility Fires

Detect early warning signs of overheating and fire hazards, protecting employees and infrastructure.

Where Can You Use MSAI Connectin Manufacturing?

Enhancing Industrial Efficiency & Safety

MSAI Connect delivers real-time monitoring and insights across key manufacturing assets.

Motors

Conveyor Belts

Critical Power Systems

Optimize Asset Reliability & Employee Safety

Enhance Productivity & Reduce Risk with MSAI Connect

MSAI Connect ’s cloud-based solutions provide real-time thermal imaging and AI-powered insights to optimize asset reliability, improve safety, and streamline predictive maintenance in manufacturing environments. Contact us today to schedule a demo.