Advanced Thermal Imaging & Software for Asset Reliability and Predictive Maintenance

Ensure peak asset performance with MSAI Connect’s AI-powered thermal imaging and predictive maintenance solutions. Monitor, analyze, and prevent failures before they disrupt operations.

Why Choose Us

Prevent Critical Asset Failures & Safety Incidents

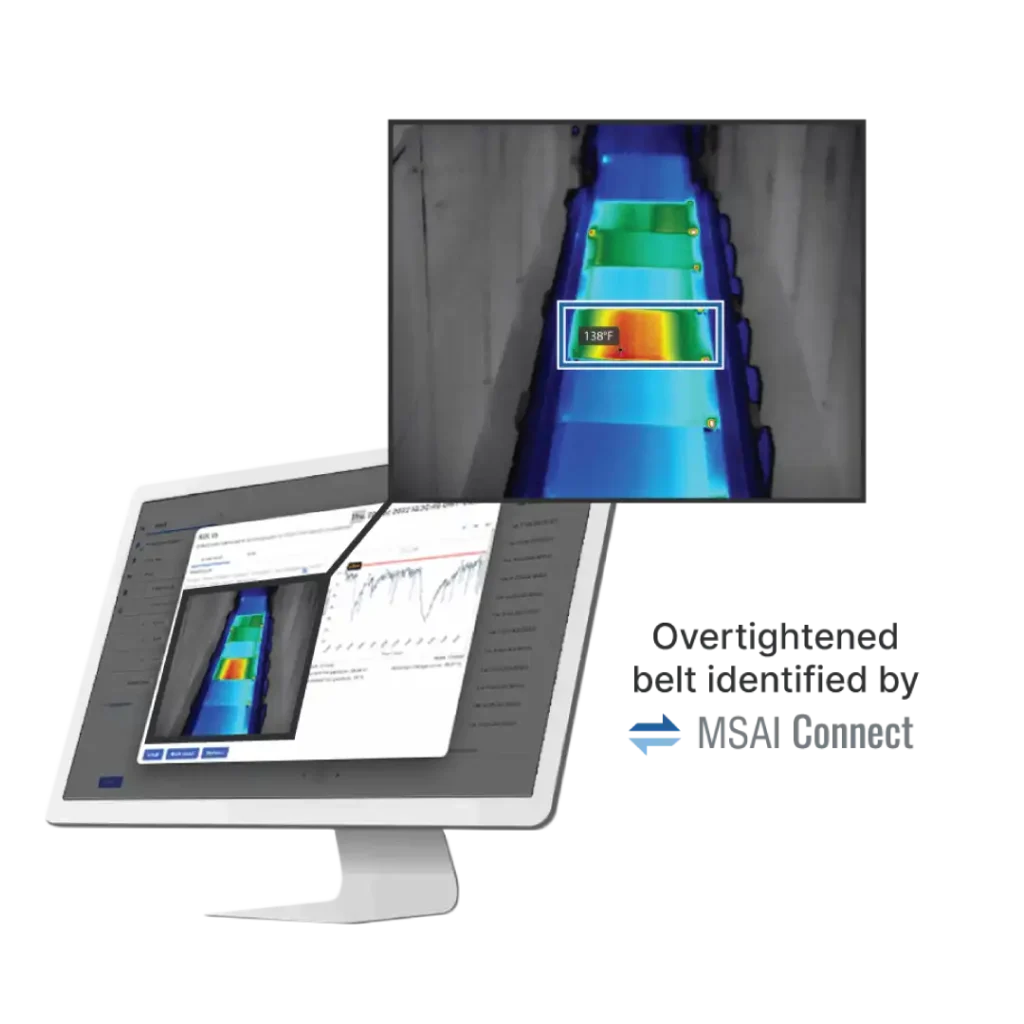

MSAI Connect transforms thermal imaging and sensing data into actionable insights, identifying potential failures before they occur. With AI-driven analytics and predictive maintenance, businesses can optimize operations, enhance safety, and reduce downtime.

Intelligent Condition Monitoring Platform

Why Choose MSAI Connect?

Powered by AWS, MSAI Connect offers advanced condition monitoring with AI-driven analytics, real-time video monitoring, automated alerts, and seamless integration into existing operational systems.

-

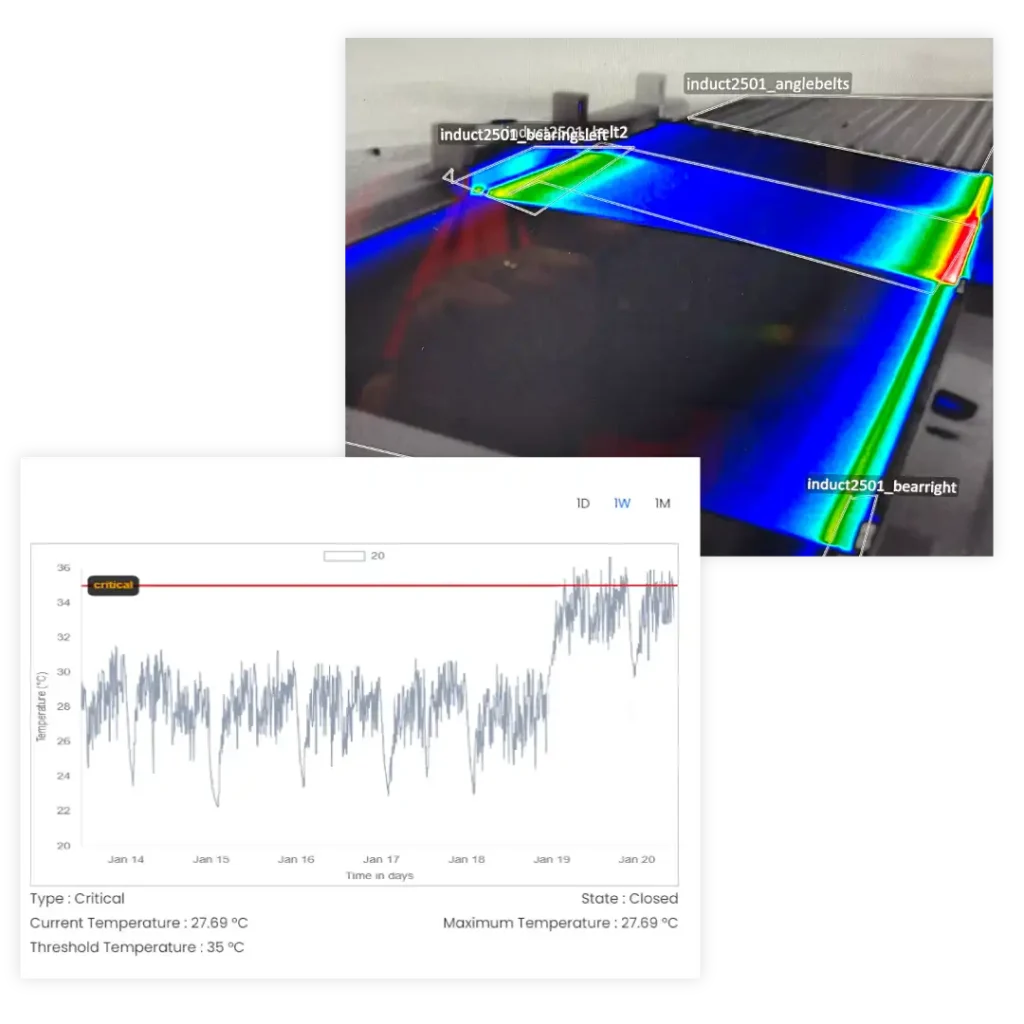

Scalable Analytics & Customizable Dashboards

MSAI Connect’s AI-powered analytics enable users to set KPIs and benchmarks, identifying temperature deviations before operational disruptions occur.

-

Real-Time On-Site or Remote Video Monitoring

AWS-powered Kinesis video streams provide real-time and archived footage from thermal cameras, accessible from anywhere.

-

Seamless Integration with VMS and DCS Systems

MSAI Connect integrates effortlessly with existing Video Management Systems (VMS) and Distributed Control Systems (DCS) for enhanced functionality.

-

Automated Alerts for Rapid Response

Receive instant notifications when temperature anomalies are detected, ensuring proactive maintenance and reduced downtime.

Where to Leverage MSAI Connect?

Optimizing Asset Performance Across Industries

MSAI Connect's advanced thermal imaging enhances efficiency and safety in critical sectors.

Distribution & Warehousing

Wastewater Facilities

Wood & Paper Manufacturing

Turn Thermal Imaging Into Actionable Insights

Predict & Prevent Failures with MSAI Connect

MSAI Connect ’s AI-driven monitoring platform delivers real-time data analysis to identify, predict, and prevent mechanical and electrical failures before they disrupt operations. Contact us today for a demo.