Why Keep Tabs on Fugitive Emissions?

Many industrial complexes use organic gases as part of their work and in some instances are even created as a byproduct. Therefore, the ability to detect any leaks of these gases is a major priority for the safety of the environment, employees, and surround populace. Industries must comply with environmental protection agency regulations that have strict rules on the emissions of greenhouse gases (GHGs) and smog forming volatile organic compounds.

Safe & Cost-Effective Emission Inspection to Meet Fugitive Emission Regulations

Thanks to the use of unmanned aerial vehicles (UAVs) and aerial optical gas imaging (OGI) cameras industries can now fly miles of pipeline, rail cars, compressors, pumps, other pressure vessels and industrial complexes to precisely pinpoint gas leaks and fugitive emissions in real time and with relative ease. This not only keeps the inspectors safe from the potentially hazardous gases, but is also a better cost alternative to potential reconstruction of the area that is emitting the leak.

Our Aerial Optical Gas Imaging (OGI) Solution

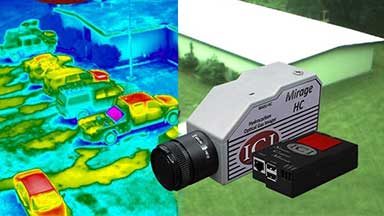

Our complete aerial sensor package includes our Mirage I640U HC and the innovative Sensor Control Module. Both products utilize aircraft grade aluminum housings that makes them lightweight for increased battery life of the drone while in flight, yet structurally sound enough to handle flight-induced vibrations and forces.

The Mirage I640U HC | Optical Gas Imaging (OGI) Thermal Infrared Camera is small and lightweight when compared to competing cooled imagers. It has the ability to detect a long list of gases including methane, benzene, smog-forming volatile organic compounds, and other toxic air pollutants. Through the use of the Indium Antimonide (InSb) cooled detectors the Mirage I640U HC allows inspection professionals to visibly see even the smallest of leaks and temperature differences in the form of a gaseous cloud within an infrared image on most Apple, Android, or Microsoft devices.

The Sensor Control Module allows for unprecedented remote control of all sensors from your drone controller. It gives you the ability to change camera parameters while in flight, including level, span, and color palettes, as well as the ability to add hot and cold spot tracking alerts. Switch quickly and easily between multiple sensors on the same quad copter to see a live video feed from both a visible and an infrared camera to identify the equipment or objects being inspected more effectively. When the drone pilot triggers an image capture, the Sensor Control Module captures images from all sensors simultaneously creating visible reference images to accompany the infrared images taken. It is also equipped with digital zoom to give you a closer look on areas of interest to better see potential problems and diagnose their severity.

Simply connect the Mirage I640U HC and the Sensor Control Module to the drone and instantly acquire the ability to fly over pipelines, rail cars, other gas transport methods and stationary industrial equipment. Span great distances, find emissions, capture unparalleled infrared images, and store the temperature data from every pixel in that image to an onboard micro SD card for later processing, all while keeping a safe distance from the leak.

These images can then be opened in ICI’s IR Flash Pro Software where further inspection can be conducted, such as the appearance of hot and/or cold spots and problem areas using traditional thermography methods while checking for any gas leaks. You also have the ability to create detailed reports directly through the software.

The Takeaway

The development of the Sensor Control Module and the new Mirage I640U HC allow inspectors and industrial facilities the ability to see otherwise invisible fugitive emissions in the most efficient and cost effective manner possible. Predictive maintenance and fugitive emission detection from manned and unmanned aerial vehicles is now possible from a safe distance and will help any company storing or transporting hazardous hydrocarbon gas to find leaks that might otherwise go unnoticed. The end results prevent product losses, pollutant emissions, and hefty fines, and create a safer environment for those working in such facilities as well as for surrounding communities.

Need More?

ICI has knowledgeable staff to support their customers with off-the-shelf solutions as well as custom builds depending on the specific application. While the Mirage I640U HC is specifically designed to detect hydrocarbon emissions, the entire Mirage series line of cameras encompasses detection of many other VOCs and GHGs such as SF6, refrigerants, CO2, CO and many more.