Automate Asset Reliability in Distribution Facilities

Why Choose Us

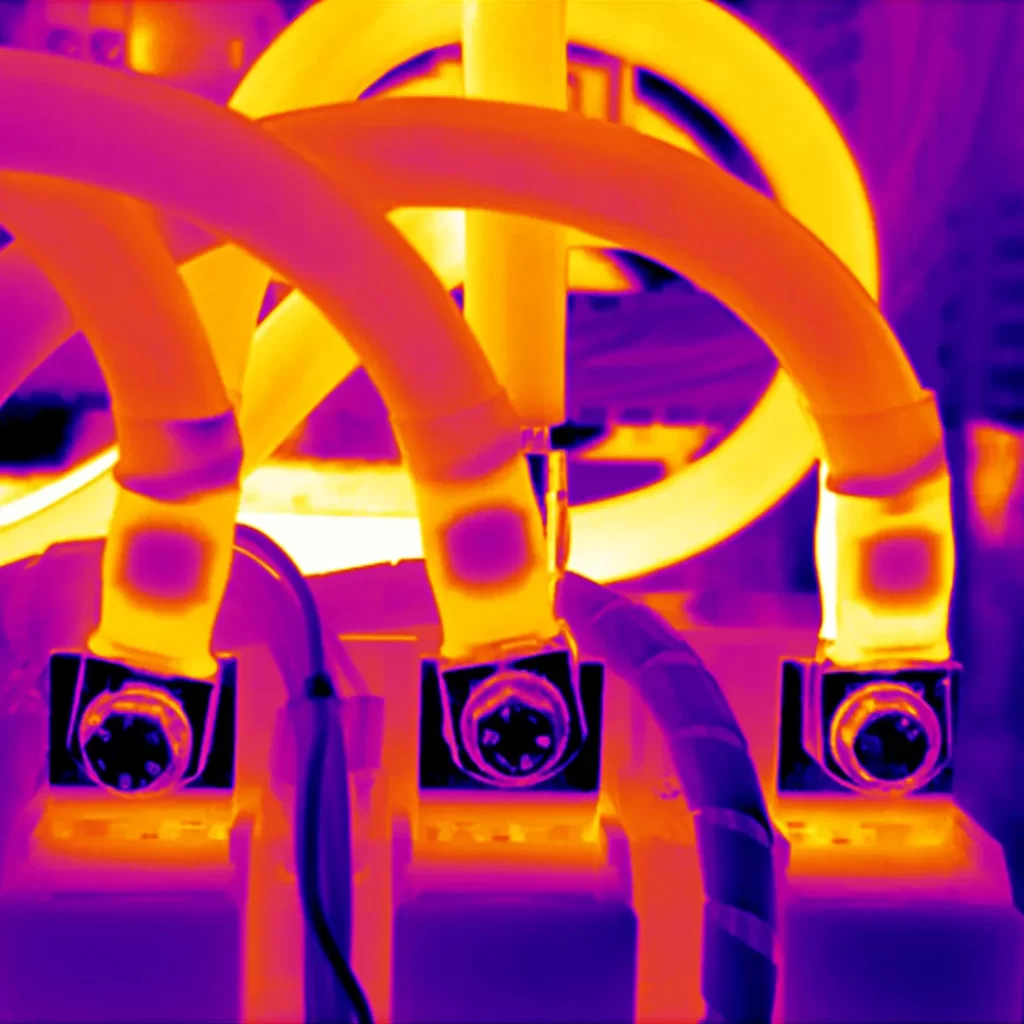

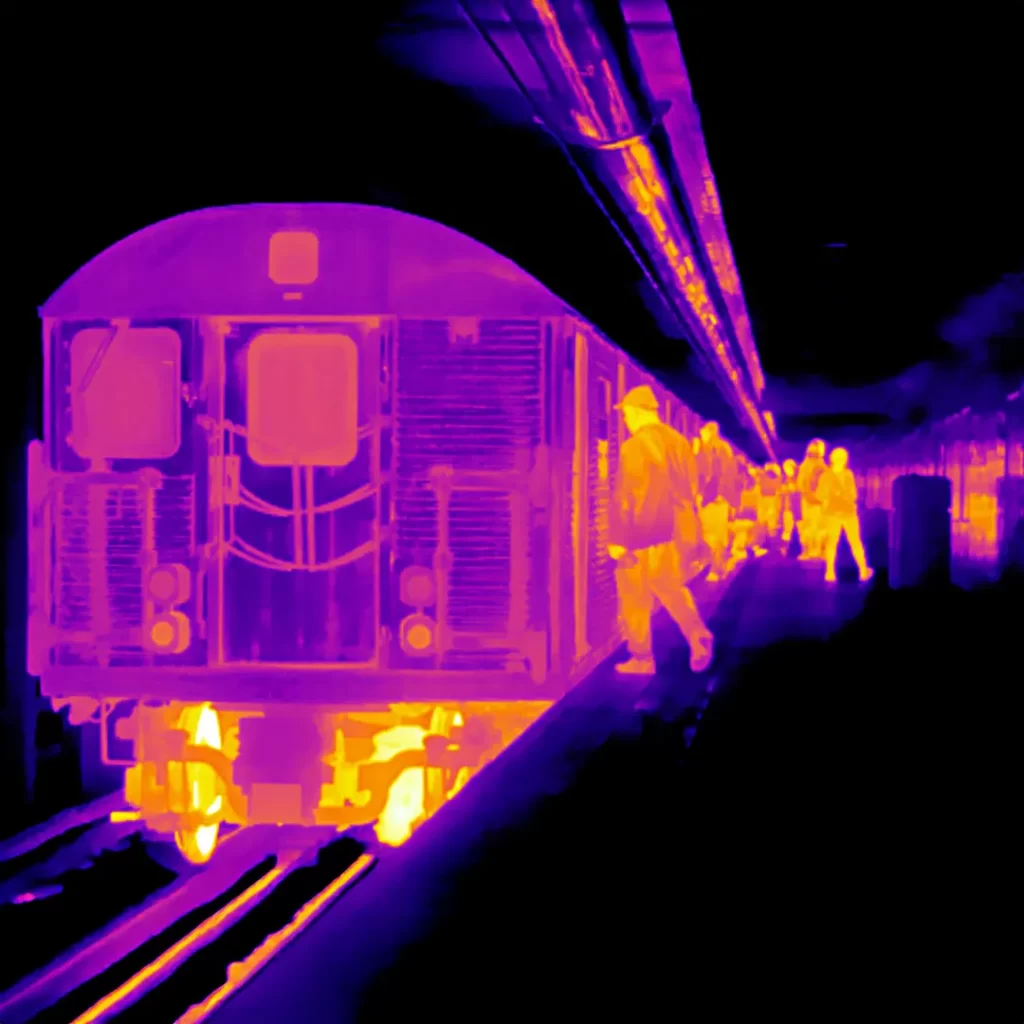

Thermal Technology in Distribution Facilities

Thermal imaging technology, powered by solutions like MSAI Connect, is transforming distribution facilities and warehouses by detecting temperature anomalies, identifying hotspots in electrical systems, and predicting equipment malfunctions. This innovation enhances safety, prolongs asset lifespan, prevents costly downtime, and ensures proper handling of temperature-sensitive products. By integrating thermal imaging into daily operations, facilities can optimize asset management, improve efficiency, and boost overall productivity.

SmartIR Distribution and Logistics

Why MSAI Connect?

MSAI Connect provides holistic coverage of critical mechanical and electrical assets in distribution facilities and warehouses, including conveyance systems, bearings, gearboxes, motors, critical power assets, and more.

-

Optimize Predictive Maintenance

Enhance asset reliability by predicting issues before they arise, ensuring uninterrupted performance.

-

Avoid Downtime and Wage Stagnation

Prevent operational delays and protect worker productivity with efficient asset management.

-

Maximize Asset Lifespan

Reduce repair costs and replacements by maintaining equipment at peak efficie

-

Limit Safety Risks

Mitigate hazards like facility fires and ensure a safe work environment with proactive measures

Why Choose Us

Using MSAI Connect in Distribution Facilities

Thermal imaging technology, powered by solutions like MSAI Connect, is transforming distribution facilities and warehouses by detecting temperature anomalies, identifying hotspots in electrical systems, and predicting equipment malfunctions. This innovation enhances safety, prolongs asset lifespan, prevents costly downtime, and ensures proper handling of temperature-sensitive products. By integrating thermal imaging into daily operations, facilities can optimize asset management, improve efficiency, and boost overall productivity.

Conveyor Belts

Motors

Critical Power

Fixed Mounted Solutions Paired with MSAI Connect

Imaging Solutions