Introduction

Methane emissions have become a major focus of environmental regulations, with the U.S. Environmental Protection Agency (EPA) introducing stricter guidelines to curb greenhouse gas emissions. The EPA methane regulations are designed to mitigate climate change impacts by requiring industries to monitor and reduce methane leaks. One of the most effective ways to ensure compliance with these regulations is through infrared technology, which provides real-time, accurate detection of methane emissions.

Infrared cameras play a crucial role in environmental monitoring, helping industries such as oil and gas, power generation, and manufacturing adhere to regulatory standards. This blog explores how infrared technology can assist businesses in meeting EPA emissions technology requirements, aligning with the New Quad O standards, Quad OA standards, and OOOOA standards while also addressing the need for SF6 leak detection and sulfur hexafluoride leak detection.

Understanding EPA Methane Regulations

The EPA methane regulations are designed to monitor and reduce methane emissions from key industries, primarily oil and gas operations. These regulations fall under the broader framework of the Clean Air Act and include:

- New Source Performance Standards (NSPS) for Oil and Gas: These require companies to limit emissions from new, modified, and reconstructed sources.

- New Quad O Standards (Quad Oa and Quad OOOOa): These impose stricter leak detection and repair (LDAR) requirements on oil and gas facilities.

- Mandatory Reporting of Greenhouse Gases (GHG): Facilities emitting above a certain threshold must report their methane emissions to the EPA.

Failure to comply with these regulations can result in hefty fines, reputational damage, and potential shutdowns. This is where infrared technology becomes essential in detecting and addressing methane leaks before they become compliance issues.

The Role of Infrared Technology in Methane Detection

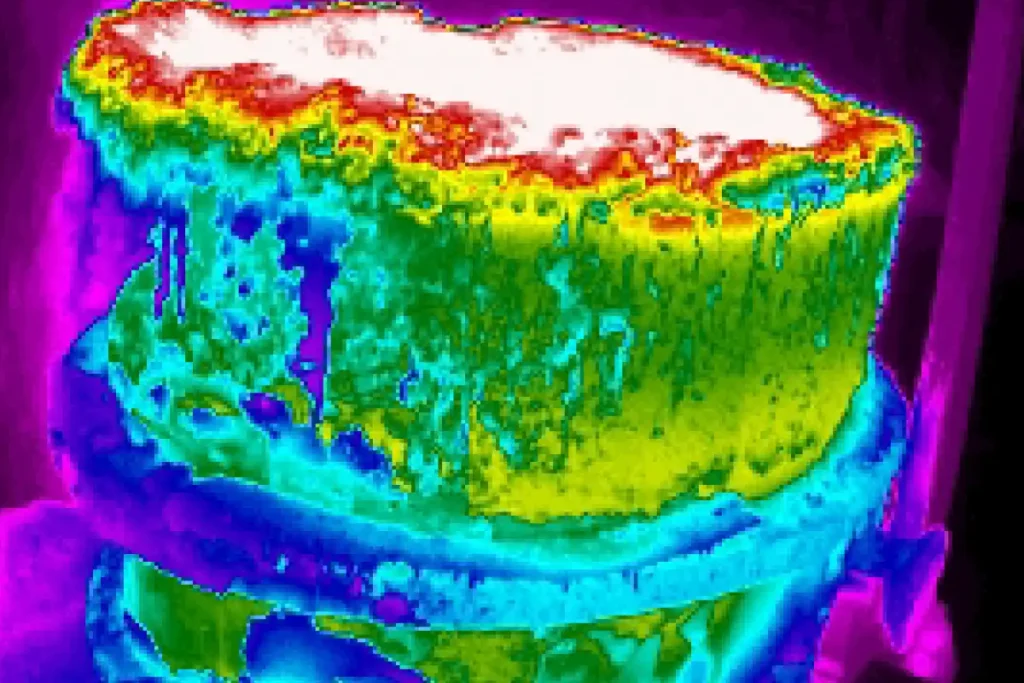

Infrared cameras are revolutionizing methane detection by providing non-contact, real-time monitoring of emissions. Unlike traditional gas detectors, which require close proximity and manual sampling, infrared cameras detect methane leaks from a distance, allowing for safer and more efficient inspections.

Key Benefits of Infrared for Methane Leak Detection

- Precision and Accuracy: Infrared imaging can detect methane leaks invisible to the naked eye, making it easier to identify problem areas.

- Cost Savings: Early detection of leaks helps prevent costly fines and repairs associated with non-compliance.

- Efficiency: Surveys with infrared cameras take less time compared to traditional manual inspections.

- Safety: Detecting leaks from a distance reduces exposure to hazardous gases for workers.

Compliance with New Quad O and Quad OA Standards

The New Quad O standards and Quad OA standards (also referred to as Quad OOOOa standards) are integral to reducing methane emissions from oil and gas facilities. These standards require companies to implement leak detection and repair (LDAR) programs, which include frequent inspections and prompt repairs.

Infrared cameras streamline compliance by enabling continuous, remote monitoring of facilities. Instead of sending personnel to manually check for leaks, companies can deploy fixed or handheld infrared cameras to monitor emissions in real time. This reduces operational downtime and ensures companies meet the stringent Quad O standards.

SF6 Leak Detection and Its Role in Compliance

Beyond methane emissions, sulfur hexafluoride (SF6) leak detection is another critical component of environmental compliance. SF6 is a potent greenhouse gas used in electrical power distribution and high-voltage equipment. Because it has a global warming potential (GWP) 23,500 times higher than CO2, detecting and preventing leaks is crucial.

Infrared technology excels in SF6 leak detection, allowing industries to:

- Identify leaks in gas-insulated switchgear (GIS) and transformers.

- Monitor SF6 emissions to stay compliant with EPA reporting requirements.

- Reduce environmental impact and avoid penalties associated with excessive SF6 leaks.

By integrating infrared solutions for both methane and SF6 leak detection, businesses can ensure comprehensive compliance with EPA emissions technology regulations.

Advancements in EPA Emissions Technology

The future of EPA emissions technology is evolving rapidly, with infrared imaging at the forefront of compliance and monitoring solutions. Modern infrared cameras now incorporate machine learning and artificial intelligence (AI) to improve detection accuracy and automate reporting. Some of the latest advancements include:

- Automated Leak Detection Systems: AI-powered infrared cameras can detect, quantify, and report methane leaks without manual intervention.

- Cloud-Based Monitoring: Remote monitoring platforms allow real-time access to emissions data, helping businesses act swiftly on potential compliance issues.

- Integration with Drones: Infrared-equipped drones are being used for large-scale inspections of pipelines, refineries, and storage facilities.

These innovations are making it easier for industries to comply with EPA methane regulations, ensuring a proactive approach to emissions reduction.

EPA Methane Regulations and ICI

With increasing regulatory pressure to limit methane and other greenhouse gas emissions, infrared technology has become a critical tool for ensuring compliance with EPA methane regulations, New Quad O standards, Quad OA standards, and OOOOA standards. By leveraging infrared cameras for SF6 leak detection and sulfur hexafluoride leak detection, industries can avoid costly fines, improve environmental sustainability, and streamline emissions monitoring.

As EPA emissions technology continues to advance, adopting infrared-based detection solutions will not only help businesses stay compliant but also enhance operational efficiency and environmental responsibility. Investing in state-of-the-art infrared solutions today will prepare industries for the evolving regulatory landscape of tomorrow.