In today’s fast-paced industrial landscape, keeping operations running smoothly is critical. Gone are the days of reactive maintenance, where teams fix machines after they fail. Instead, companies are turning to predictive maintenance — a smarter, data-driven approach that anticipates issues before they happen. And at the center of this innovation? The powerful combination of thermal imaging and the Internet of Things (IoT).

These two technologies are revolutionizing how businesses monitor equipment, reduce downtime, and cut costs. Let’s explore why thermal imaging and IoT are the future of predictive maintenance — and how they’re already reshaping industries across the globe.

What Is Predictive Maintenance?

Predictive maintenance (PdM) is a proactive strategy that uses real-time data to predict when a piece of equipment will fail — so it can be serviced just in time. Unlike reactive maintenance (which waits for breakdowns) or preventive maintenance (which follows fixed schedules), predictive maintenance leverages sensor data and analytics to intervene only when necessary.

This strategy not only saves money by avoiding unnecessary repairs but also prevents catastrophic failures, improves worker safety, and extends equipment lifespan. It’s no wonder predictive maintenance has become a top priority across manufacturing, energy, and transportation sectors.

The Role of Thermal Imaging in Maintenance

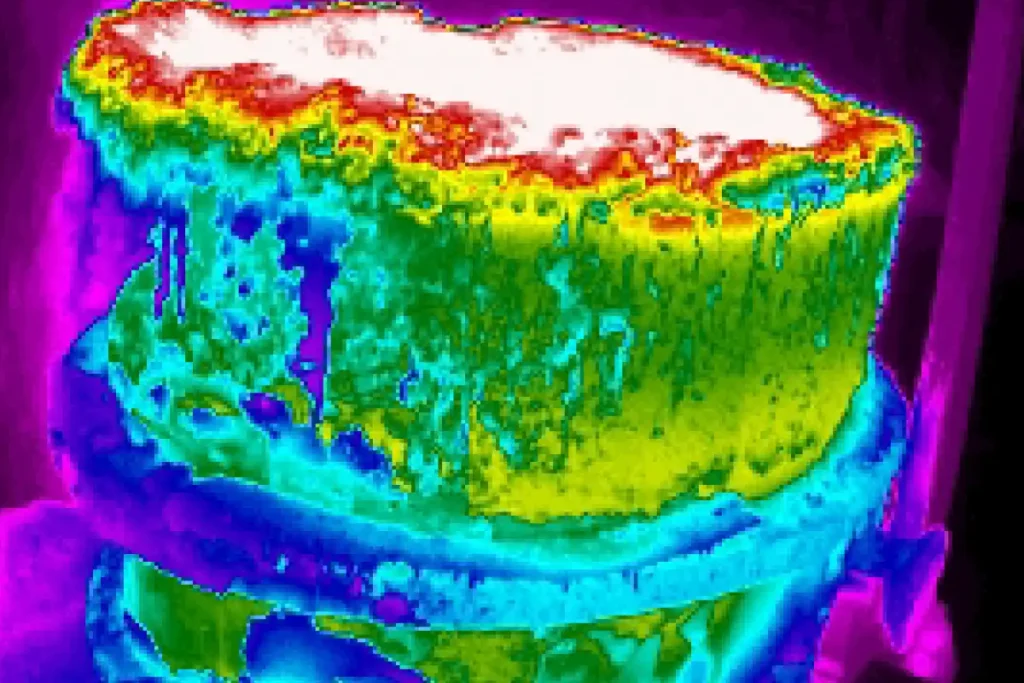

Thermal imaging is a key enabler of predictive maintenance. By detecting heat patterns and anomalies, thermal cameras provide early warnings about components that are overheating — often a telltale sign of failure in the making.

Whether it’s an electric motor generating excess friction, a failing HVAC unit, or a transformer about to short, thermal imaging lets maintenance teams “see” the invisible problems before they cause major damage. And with non-contact technology, inspections can be done safely and efficiently — even on equipment that’s live or difficult to access.

IoT: The Backbone of Smart Monitoring

The Internet of Things (IoT) refers to the network of connected sensors, devices, and software platforms that collect and exchange data. In industrial settings, IoT has transformed maintenance into a continuous, real-time process.

Tiny, low-power sensors can now monitor temperature, vibration, current, humidity, and other variables — feeding data into cloud platforms for analysis. Maintenance teams can receive alerts, generate reports, and view equipment status from anywhere.

And when thermal imaging is part of this ecosystem, the value multiplies. High-resolution thermal cameras, integrated with IoT networks, bring visual context to sensor readings — making it easier to diagnose and act.

How Thermal Imaging and IoT Work Together

When thermal imaging and IoT are integrated, they create a powerful predictive maintenance system. Here’s how it typically works:

- Thermal cameras are installed in key locations — monitoring electrical panels, rotating machinery, pipelines, or compressors.

- These cameras are connected to IoT gateways that continuously upload images and temperature data to a centralized platform.

- AI algorithms and analytics software scan the data for unusual patterns or rapid changes in heat signatures.

- When an anomaly is detected, an automated alert is sent to maintenance personnel — complete with thermal visuals, time stamps, and severity ratings.

Instead of monthly inspections or manual checks, this setup offers 24/7 automated oversight — reducing the chances of missing critical signs of failure.

Real-World Applications

The impact of thermal imaging and IoT can be seen across a variety of industries:

Manufacturing

Detecting misaligned shafts, worn bearings, and electrical overloads is vital for uptime. Smart thermal systems alert engineers before motors seize or circuits fry — preventing costly production stops.

Energy

In substations and power plants, thermal cameras monitor transformers, switchgear, and insulation. With IoT, utilities can track temperature trends over time — spotting degradation and avoiding blackouts.

Transportation

From monitoring brakes and bearings in rail systems to ensuring proper electrical function in fleets, thermal imaging helps reduce delays and improve passenger safety.

Benefits of the Integration

Combining thermal imaging and IoT offers major benefits:

- Minimized Downtime

Spotting problems early means fewer breakdowns and more consistent operations. - Lower Maintenance Costs

Targeted repairs eliminate unnecessary part replacements and reduce labor hours. - Extended Equipment Life

Keeping machines running within safe temperature ranges reduces wear and tear. - Improved Safety

Workers can identify overheating components without physical contact — reducing exposure to dangerous environments. - Data-Driven Decisions

Visual heat maps and long-term trend analysis lead to smarter planning and prioritization.

Challenges and Considerations

Of course, no solution is without hurdles. Companies considering thermal + IoT systems should keep these in mind:

- Data Volume

High-resolution thermal data adds up quickly. You’ll need storage, bandwidth, and processing power to manage it. - Interpretation

While AI helps, human expertise is still needed to interpret thermal patterns accurately in complex systems. - Security

With any connected device, especially in critical infrastructure, cybersecurity must be a top priority. - Hardware Selection

Not all thermal cameras are created equal. It’s crucial to choose cameras designed for industrial IoT integration — with the right resolution, sensitivity, and connectivity features.

What’s Next for Infrared and IoT?

As technology evolves, we’re seeing the next wave of advancements:

- AI-Powered Insights

Machine learning is being trained to detect subtle anomalies in thermal data — making alerts more accurate and reducing false positives. - Mobile & Drone Integration

Portable thermal cameras and aerial drones are enabling inspections in hard-to-reach or hazardous areas — especially in oil & gas and utilities. - Wider Adoption

As costs decrease, even mid-sized operations are adopting smart thermal systems to stay competitive and compliant.

Let’s Build a Smarter Maintenance Strategy

Whether you’re in energy, manufacturing, or transportation, predictive maintenance with thermal imaging and IoT is a game-changer. At Infrared Cameras Inc., we offer custom thermal solutions designed to integrate seamlessly with your IoT ecosystem — helping you reduce downtime, improve safety, and future-proof your operations.

Ready to modernize your maintenance approach? Contact us today to learn how ICI’s intelligent infrared systems can keep your business running at peak performance.