Understanding the Importance of SF6 Leak Detection

Sulfur hexafluoride (SF6) is a widely used gas in various industrial applications, particularly in electrical equipment such as circuit breakers, switchgear, and transformers. Despite its effectiveness as an insulating gas, SF6 is also one of the most potent greenhouse gases, with a global warming potential (GWP) over 23,000 times that of carbon dioxide. This makes SF6 leak detection crucial for industries that rely on this gas, not only for environmental compliance but also for cost savings and safety.

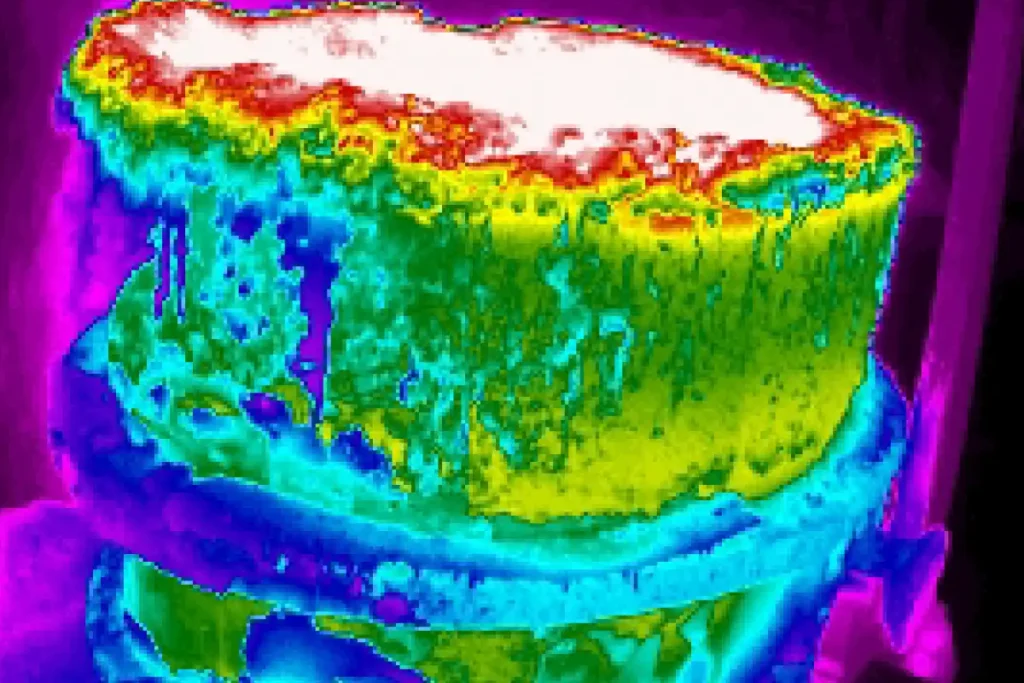

As regulatory bodies like the EPA tighten emissions technology requirements, companies must take proactive steps to minimize SF6 emissions. Infrared cameras have emerged as one of the most effective tools for detecting and mitigating SF6 leaks. This blog will explore the significance of sulfur hexafluoride leak detection, how infrared cameras contribute to emissions reduction, and what industries can do to stay compliant with EPA emissions technology standards.

Why SF6 Leak Detection is Critical

Environmental Impact

SF6 is classified as a long-lived greenhouse gas due to its atmospheric lifespan of up to 3,200 years. Even small leaks can contribute significantly to global warming, making leak detection and prevention a priority for industries using SF6.

Regulatory Compliance

The EPA and other international regulatory bodies have implemented strict guidelines for SF6 emissions. The U.S. EPA Greenhouse Gas Reporting Program (GHGRP) requires companies to monitor and report their SF6 usage and leaks. Non-compliance can result in heavy fines and reputational damage.

Cost Savings and Equipment Efficiency

SF6 is an expensive gas, and leaks lead to unnecessary costs. Leaking equipment also experiences increased wear and tear, reducing efficiency and potentially leading to system failures. Detecting leaks early helps reduce operational costs and improve equipment longevity.

How Infrared Cameras Help Detect SF6 Leaks

Infrared cameras, specifically designed for gas detection, provide a non-contact and highly efficient method for identifying SF6 leaks. Here’s how they work:

Optical Gas Imaging (OGI) Technology

Infrared cameras equipped with Optical Gas Imaging (OGI) can visualize SF6 gas leaks in real time. Unlike traditional detection methods, which require direct contact with the gas, OGI cameras detect emissions from a safe distance. This allows technicians to locate leaks quickly and accurately without shutting down operations.

Improved Safety and Efficiency

Manual detection techniques, such as sniffers or soap bubble testing, can be time-consuming and hazardous. Infrared cameras eliminate the need for close contact with high-voltage equipment, reducing risks and improving worker safety.

Wide Area Coverage

A single infrared camera scan can cover large areas and multiple components, making it an efficient solution for facilities with extensive SF6 usage. This is particularly beneficial for power plants, electrical substations, and manufacturing facilities where identifying leaks manually would be impractical.

Industries That Benefit from SF6 Leak Detection

Several industries rely on SF6 and must actively monitor and manage emissions:

Power Generation & Transmission

Utilities use SF6 in electrical switchgear and circuit breakers due to its superior insulating properties. Infrared cameras help detect leaks in high-voltage equipment, ensuring compliance with EPA emissions technology regulations.

Manufacturing & Industrial Applications

Semiconductor manufacturing and metal processing also use SF6 in production processes. Continuous monitoring with infrared cameras allows these industries to minimize environmental impact and adhere to emissions standards.

Research & Medical Fields

SF6 is used in certain medical applications and laboratory research. Proper leak detection is essential to prevent unnecessary exposure and ensure regulatory compliance.

Steps to Implement SF6 Leak Detection with Infrared Technology

1. Conduct Regular Inspections

Routine leak detection surveys with infrared cameras should be incorporated into standard maintenance protocols. This helps in early leak identification before they become significant problems.

2. Train Personnel on OGI Technology

Effective use of infrared cameras for SF6 leak detection requires trained operators. Investing in training programs ensures accurate identification and response to leaks.

3. Integrate Leak Detection with Compliance Programs

Companies should align their SF6 monitoring efforts with EPA emissions technology requirements. Regular reporting and documentation of leak detection efforts help demonstrate compliance with environmental regulations.

4. Invest in Advanced Detection Equipment

Upgrading to the latest infrared cameras with high sensitivity and real-time detection capabilities ensures that SF6 leaks are identified quickly and efficiently.

5. Implement Leak Prevention Measures

Beyond detection, companies must take proactive steps to reduce leaks, such as improving equipment maintenance, using leak-resistant components, and optimizing gas handling procedures.

Stay Ahead of SF6 Regulations and Protect the Environment

With increasing pressure from regulatory bodies and growing environmental concerns, implementing advanced SF6 leak detection measures is no longer optional—it’s a necessity. Industries that use SF6 must adopt infrared technology to ensure compliance, improve safety, and reduce their carbon footprint.

By investing in cutting-edge EPA emissions technology, businesses can not only meet regulatory requirements but also enhance operational efficiency and sustainability. Want to ensure your facility is SF6-compliant? Explore our range of infrared cameras for SF6 leak detection today!