The Evolving Landscape of EPA Emissions Technology

As environmental concerns continue to grow, regulatory bodies like the Environmental Protection Agency (EPA) are tightening emissions standards to minimize the impact of harmful gases on the atmosphere. EPA emissions technology has seen significant advancements in recent years, with infrared gas detection emerging as a key tool for industries striving to stay compliant.

New regulations, such as the Quad OA standards and updates to EPA methane regulations, require businesses to adopt more effective emissions monitoring solutions. Additionally, SF6 leak detection remains a critical concern due to the high global warming potential of sulfur hexafluoride. This blog will explore the latest innovations in EPA emissions technology, how infrared gas detection is transforming compliance efforts, and why industries should invest in these advancements.

Why Advanced EPA Emissions Technology Matters

Regulatory Compliance and Evolving Standards

The EPA continuously updates emissions regulations to reflect the latest environmental research. The Quad OA standards (or OOOOA standards) introduce stricter control measures for volatile organic compounds (VOCs) and methane emissions in the oil and gas sector. Staying ahead of these regulations requires businesses to adopt cutting-edge monitoring technologies.

The Need for Precision and Efficiency

Traditional emissions monitoring methods can be time-consuming, labor-intensive, and prone to inaccuracies. Infrared gas detection provides a faster, non-invasive, and highly accurate alternative, allowing for real-time leak detection and emissions tracking.

Reducing Environmental Impact

Methane and SF6 emissions contribute significantly to global warming. Investing in advanced infrared detection technologies enables industries to proactively reduce emissions and support sustainability initiatives while avoiding heavy fines.

Innovations in Infrared Gas Detection

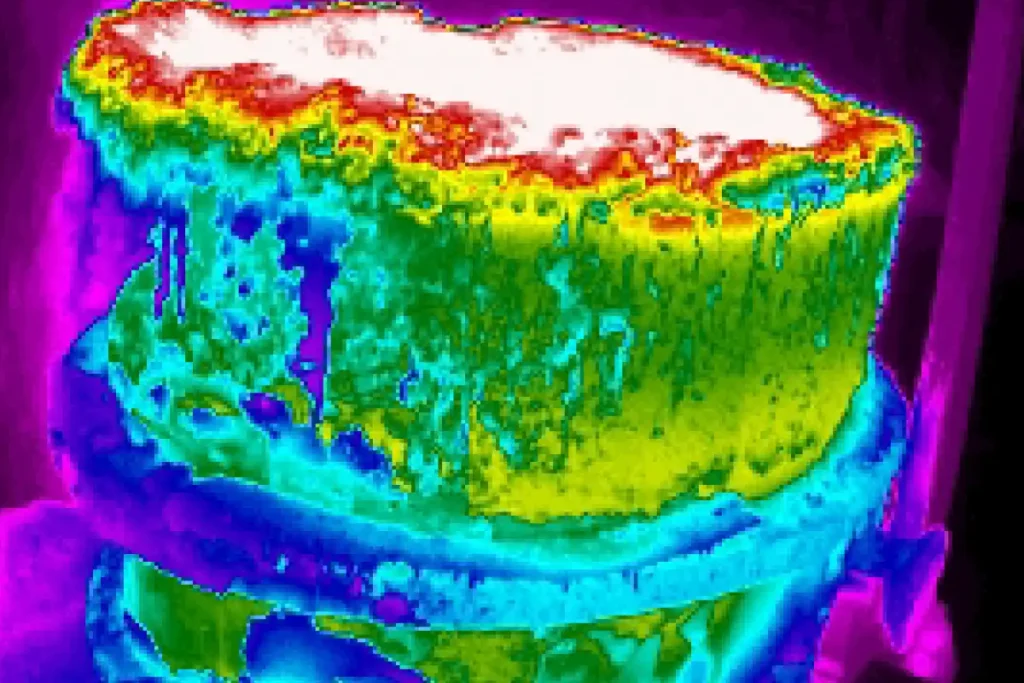

Optical Gas Imaging (OGI) for Methane and VOCs

One of the most impactful advancements in EPA emissions technology is Optical Gas Imaging (OGI), which allows industries to detect invisible gas leaks quickly and efficiently. This technology is particularly valuable for monitoring compliance with EPA methane regulations and the Quad OA standards.

- Non-contact detection: OGI cameras detect leaks from a safe distance, reducing the need for manual inspections.

- Real-time monitoring: Operators can identify leaks instantly and take immediate corrective action.

- Wide application range: OGI is used in oil and gas, power generation, and industrial manufacturing to track methane and VOC emissions.

SF6 Leak Detection with Infrared Cameras

Sulfur hexafluoride (SF6) is widely used in electrical insulation but is a highly potent greenhouse gas. Advanced infrared SF6 leak detection cameras can locate leaks in high-voltage equipment, reducing emissions and ensuring regulatory compliance.

- Enhanced sensitivity: Modern infrared cameras can detect even the smallest SF6 leaks, preventing unnecessary environmental exposure.

- Efficient maintenance: Utilities and manufacturers can integrate SF6 detection into their routine inspections to prevent costly failures.

Integration of AI and Machine Learning

The future of EPA emissions technology lies in the integration of Artificial Intelligence (AI) and Machine Learning (ML) into infrared gas detection systems. These technologies can:

- Analyze vast amounts of emissions data to identify patterns and potential risks.

- Automate detection processes, reducing the need for manual monitoring.

- Predict equipment failures before they occur, enabling proactive maintenance.

Remote Sensing and Drones for Large-Scale Monitoring

For industries operating in remote or hard-to-access locations, drone-mounted infrared gas detection systems provide a game-changing solution. These drones can:

- Survey large areas quickly and efficiently.

- Pinpoint emissions sources in real-time.

- Minimize safety risks by eliminating the need for human inspectors in hazardous areas.

Applications of Advanced Infrared Gas Detection

Oil and Gas Industry Compliance with Quad OA Standards

The oil and gas sector is a primary target for Quad OA standards, which focus on reducing methane leaks and VOC emissions. Infrared cameras and OGI technology help companies:

- Meet EPA methane regulations with accurate, non-intrusive monitoring.

- Reduce fugitive emissions, which can lead to regulatory fines.

- Enhance operational efficiency by quickly identifying and fixing leaks.

Utility Sector: Managing SF6 Emissions

Utilities using SF6-insulated equipment must adhere to strict SF6 leak detection protocols. With infrared cameras, power plants and substations can:

- Monitor emissions in real time, ensuring compliance with EPA emissions technology regulations.

- Extend equipment lifespan by addressing leaks before they lead to failures.

- Minimize the environmental footprint of SF6 usage.

Industrial Manufacturing: VOC and Greenhouse Gas Control

Many manufacturing processes release volatile organic compounds (VOCs) and other greenhouse gases. Implementing infrared gas detection allows manufacturers to:

- Improve air quality and worker safety by reducing exposure to harmful emissions.

- Optimize production efficiency by detecting and addressing leaks early.

- Comply with evolving EPA regulations, avoiding legal and financial repercussions.

Preparing for the Future of EPA Emissions Technology

As regulatory expectations continue to increase, industries must take a proactive approach to emissions monitoring. Companies that invest in advanced infrared gas detection technology will be better positioned to:

- Achieve regulatory compliance with minimal disruption.

- Reduce emissions costs by preventing leaks and inefficiencies.

- Demonstrate environmental responsibility, enhancing their reputation and market competitiveness.

The next generation of EPA emissions technology is already transforming how industries monitor and reduce harmful emissions. By adopting infrared gas detection solutions, businesses can stay ahead of regulatory changes, improve operational efficiency, and contribute to a more sustainable future. Interested in the latest infrared technology for emissions compliance? Explore our cutting-edge solutions today!