Substation Monitoring

Electrical substations are vital components of the power grid and need to be safe, reliable, and efficient in order to keep utilities running smoothly. Our SmartIR software proactively identifies potential issues, allowing utilities to prevent accidents, minimize downtime, optimize operations, comply with regulations, and effectively manage their assets. By using SmartIR to identify issues proactively, utilities can minimize risks, improve efficiency, and keep the lights on for their valued customers.

Identifying Substation Issues

SmartIR's generative AI-powered algorithm is able to identify and diagnose potential upcoming issues within substations, allowing organizations to swiftly address the potential cause of failure.

Overloaded Circuits

Imbalanced Loads

Malfunctioning Equipment

Insulation Issues

Cooling System Problems

SmartIR Applied

Intelligent Condition Monitoring

SmartIR leverages continuous monitoring and AI-powered algorithms to identify and analyze critical maintenance issues and efficiency improvement opportunities that go beyond conventional inspection methods.

Gain data driven insights to optimize the lifespan and performance of substation equipment

Predict and prevent problems with transformers, busbars, surge arresters, current transformers, bushings, and more to avoid costly downtime and improve safety

Maintain higher energy efficiency levels by identifying faulty insulators and capacitors

Get automatically notified if equipment starts operating outside of prescribed limits, helping meet regulatory requirements and environmental standards

SmartIR for Substation Monitoring

Substations are the backbone of electric utility operations, playing a vital role in power distribution, reliability, load management, grid expansion, and integration of renewable energy. SmartIR is perfect for electric utilities organization looking to reduce costs, improve reliability, enhance safety protocols, optimize asset management, and operate more efficiently.

Infrared Technology Applied

Why Infrared Technology is so Effective

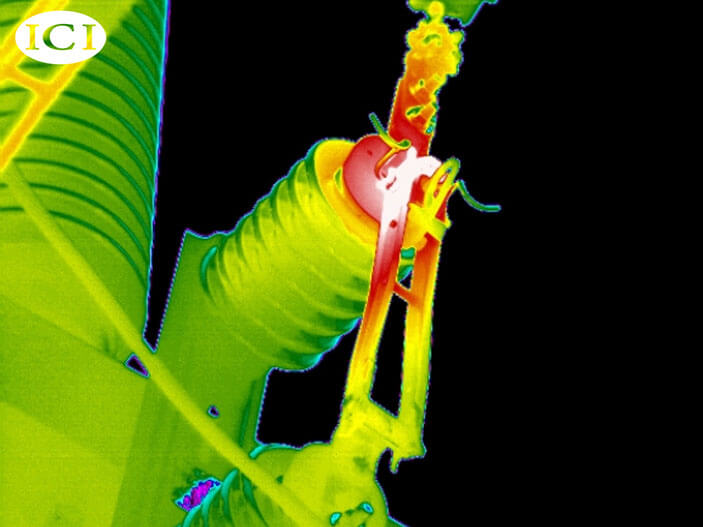

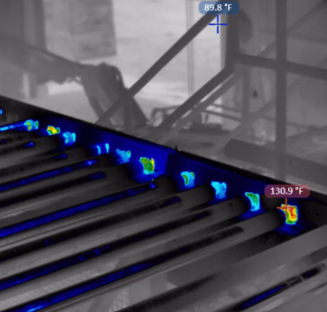

Thermal images provide temperature data useful in many different aspects. They allow you to see immediate issues such as hotspots, but they also allow you to see gradual changes in temperature overtime that could indicate a developing problem.

Hotspots, which are areas with a higher temperature compared to their surroundings, often indicate potential issues such as friction, misalignment, overloading, or equipment malfunctions. Hotspots are easily identified with thermal cameras, helping prevent equipment failures and minimizing unplanned downtime.

With a complete thermal data set, you can identify more issues and areas for improvement. For example, if you know the normal temperature range for your conveyor belts, you can identify unusual temperature spikes or drops that may signify a malfunctioning component, a material blockage, or other issues that need immediate attention. You can find patterns that repeat themselves, giving you insights on specific materials that could be causing excessive friction or stress on the belt system. By analyzing trends, patterns, and anomalies, you can predict when problems might occur allowing you to schedule maintenance before failure occurs.

Data sets also allow you to understand how your belt system performs under different conditions by identifying factors that affect temperature such as speed, material type, or environmental factors to optimize performance, reduce energy usage, and improve overall efficiency.

Simply put, infrared technology allows you to efficiently schedule maintenance, detect issues early, optimize performance, and ensure reliably.

Infrared Technology Applied

Why Infrared Technology is so Effective

Thermal images provide temperature data useful in many different aspects. They allow you to see immediate issues such as hotspots, but they also allow you to see gradual changes in temperature overtime that could indicate a developing problem.

Hotspots, which are areas with a higher temperature compared to their surroundings, often indicate potential issues such as friction, misalignment, overloading, or equipment malfunctions. Hotspots are easily identified with thermal cameras, helping prevent equipment failures and minimizing unplanned downtime.

With a complete thermal data set, you can identify more issues and areas for improvement. For example, if you know the normal temperature range for your conveyor belts, you can identify unusual temperature spikes or drops that may signify a malfunctioning component, a material blockage, or other issues that need immediate attention. You can find patterns that repeat themselves, giving you insights on specific materials that could be causing excessive friction or stress on the belt system. By analyzing trends, patterns, and anomalies, you can predict when problems might occur allowing you to schedule maintenance before failure occurs.

Data sets also allow you to understand how your belt system performs under different conditions by identifying factors that affect temperature such as speed, material type, or environmental factors to optimize performance, reduce energy usage, and improve overall efficiency.

Simply put, infrared technology allows you to efficiently schedule maintenance, detect issues early, optimize performance, and ensure reliably.

FAQ: Building Science

What can infrared cameras catch in a roof inspection?

Thermal cameras excel at detecting pest invasions, roof leaks, ice damming, and many other common roof problems on commercial or residential buildings. Unmanned cameras on drones help ensure the safety of your inspectors while upholding the quality of the inspection.

How can thermal cameras help with advanced building science?

Our thermal cameras are designed to complete infrastructure inspections and monitor advanced building science activities. Our technology can be utilized during the construction process by being added to drone systems or by enhancing visual inspections with a handheld thermal camera. These tools aid searching buildings for efficiency in energy, insulation, and water.

Keep up with Infrared Cameras Inc.

Top Employer Guidelines for a Safer Return to Work

Temperature Screening Hospitality Guidelines for Safer Stays

How Hospital Service has Changed to Slow COVID-19 Spread

Preventative Maintenance and Thermal Imaging Authorities

Infrared solutions are our specialty. Find out why we have been in the industry for 25 years.