Electrical Inspections with Infrared

A small electrical problem can quickly turn into a system-wide shutdown. Until your team finds and replaces the faulty equipment, production comes to a halt. Infrared electrical inspections can help ensure an operation never reaches that point. By finding damaged components early, infrared energy audits allow you to plan for repairs and prevent downtime. They are essential to maintaining a productive business and an efficient electrical system.

ICI provides unbeatable, highly accurate electrical inspection solutions. Our infrared systems quickly detect high temperatures, which are an early sign of failing equipment or fire hazard. Inspect your entire electric power distribution system and see what the eye would normally miss. From facility monitoring to new home inspections, ICI’s solutions keep things safe and moving forward.

What happens in an electrical safety check?

During a new system installation or a routine electrical inspection, safety is key. It is important to identify any damaged equipment or parts that were incorrectly made or installed. Infrared energy audits make this task easier by overviewing your whole system, even hard to reach or see areas. Infrared cameras identify hot spots, which indicate increased resistance in electrical equipment. These hot components might be failing, or worse, might soon burn.

Electrical professionals use infrared inspections for regular preventative and predictive maintenance checks. Inspections also help ensure a business meets guidelines for safe installation and operation. Landlords and homeowners rely on infrared inspection to stay up to permit codes or meet insurance requirements. Whatever the application, infrared electrical inspection helps keep people safer.

What is electrical thermal scanning?

Electrical thermal scanning uses an infrared camera to create a high-resolution temperature map. In an infrared electrical inspection, this image identifies hot spots and helps you catch issues early on. You can identify hazardous equipment before it fails, before it melts, or corrodes other components.

Infrared is useful for checking switchboards, electrical cabinets, insulation, transformers, connectors, and more. Find overloaded equipment, corrosion, loose connections, and damage or deterioration of all kinds. Plan ahead and keep business moving with infrared energy audits.

Identify electrical issues early

Predict maintenance and prevent downtime

Prevent electrical fires

Expert advice and continuous support

Find the right electrical inspection solution.

Unmanned Thermal Cameras

Handheld Thermal Cameras

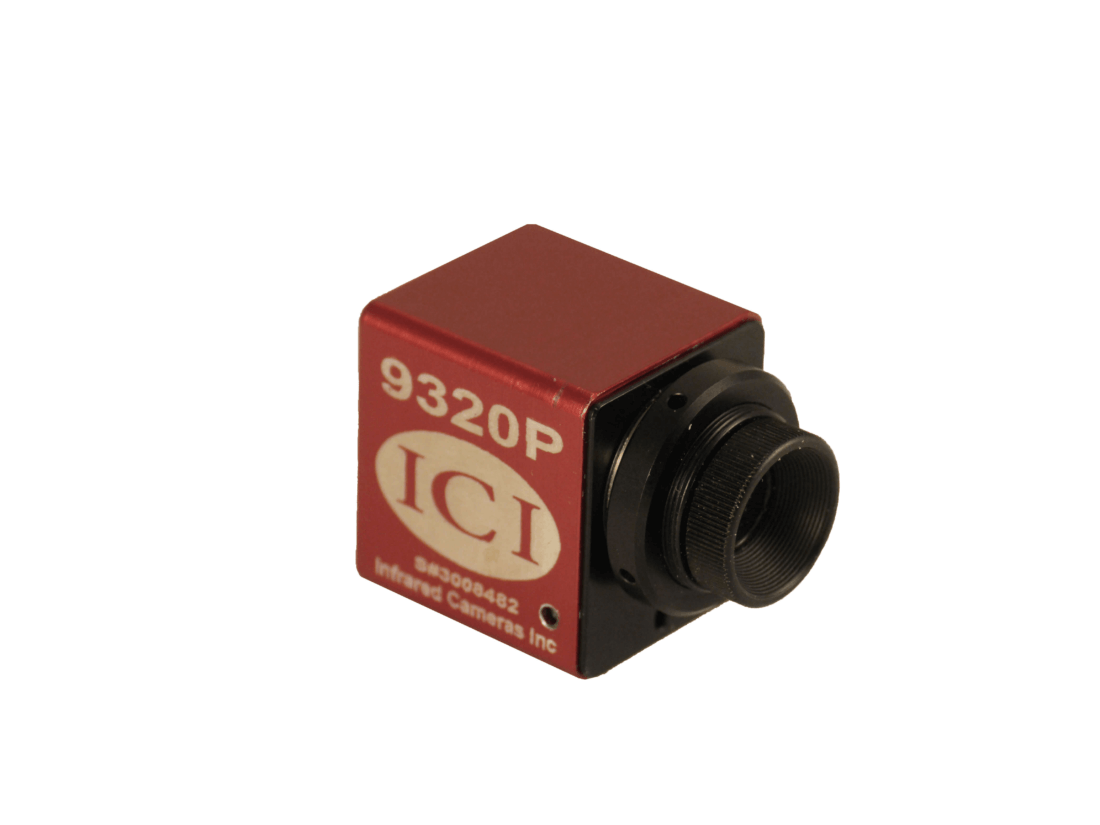

Fixed Mount Thermal Cameras

Where can you utilize infrared cameras in electrical safety inspections?

Ensure that new and existing electrical systems are up to permit safety codes and insurance requirements. Catch hot spots in circuitry, connections, fuses, and more.

Keep families and tenants safe with infrared electrical testing. Ensure that new and existing installations are up to safety codes and free of hot spots.

Benefits of Infrared Electrical Inspection

Infrared electrical testing increases safety and productivity while saving you money. They can help any facility, commercial, or residential building. Benefits include fire and arc flash prevention, less downtime, and fewer losses. Infrared energy audits catch issues early so that you can plan for maintenance and make equipment last longer. Non-invasive and contactless, infrared also allows you to monitor equipment without stopping operation. It is an unmatched tool for prevention and smooth operation.

- Prevent dangerous fires and arc flashes.

- Stay up to safety codes and insurance requirements.

- Prevent system shutdowns and downtime.

- Plan for repairs and maintenance.

- Lengthen equipment life.

Keep up with Infrared Cameras Inc.

Top Employer Guidelines for a Safer Return to Work

Temperature Screening Hospitality Guidelines for Safer Stays

How Hospital Service has Changed to Slow COVID-19 Spread

Infrared electrical inspections with expert training and support.

ICI provides highly accurate infrared solutions for every electrical application. Industry leaders and innovators since 1995, we're here to help you find the perfect system for a safer, more productive workplace or home. Learn more about ICI's unmatched infrared technology, expert advice, training, and support.