Thermal Imaging for the Oil and Gas Industry

From exploration and production to transportation and refinement, operators in every stream of the oil and gas industry turn to infrared cameras. Thermal imaging makes the workplace safer, more profitable, and more environmentally friendly. In a facility that deals daily with invisible gases, thermal cameras bring it all into view to make your job easier. Infrared technology easily conducts tank and flare monitoring as well as performing oil well imaging. They also can locate hot spots on pressure vessels and assist in water and wastewater management for the oil and gas industry. We are here to help you find the right infrared cameras to keep your oil and gas operation safe and efficient.

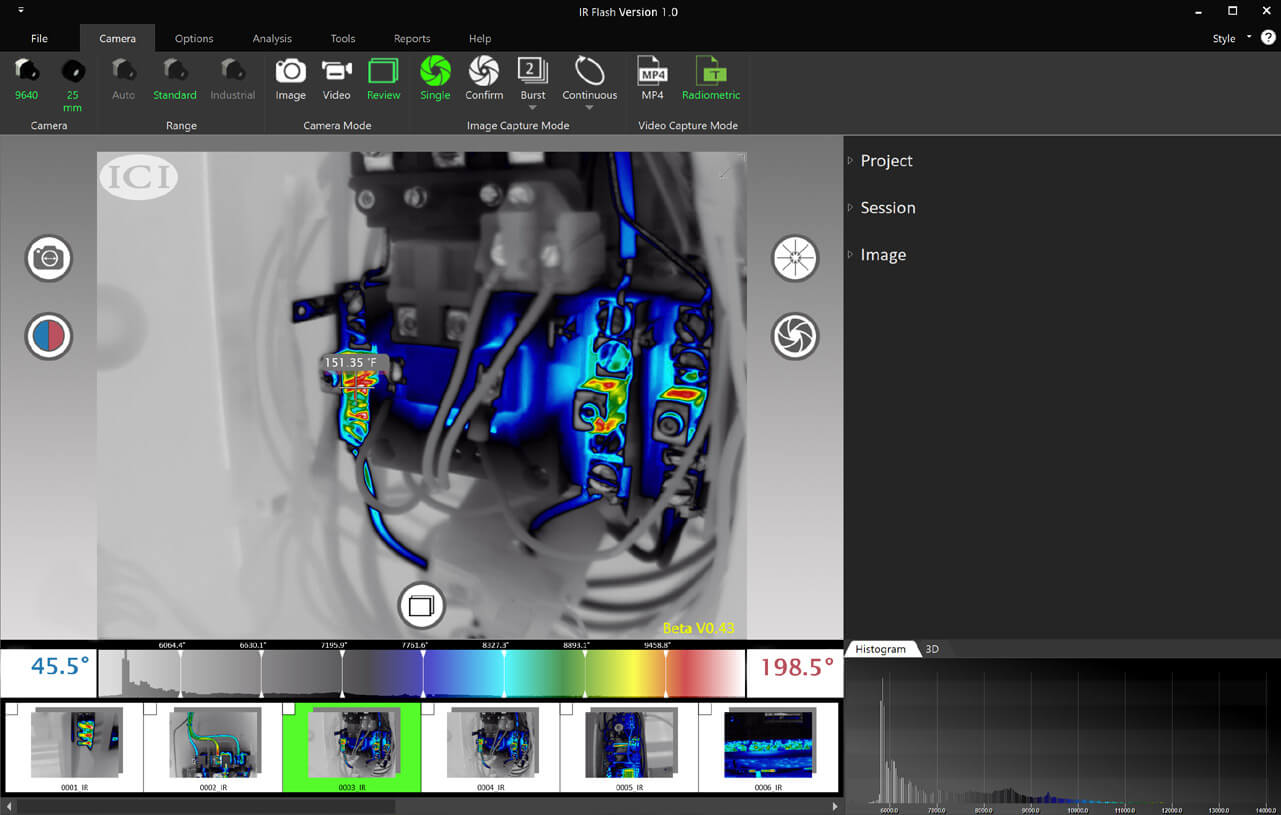

How does a thermal camera conduct a gas leak inspection?

Specialized infrared cameras use Optical Gas Imaging (OGI) to show the presence of methane, hydrocarbon, and other gases during an equipment or pipeline inspection procedure. They provide a contactless way to detect safety and production issues and are especially useful in hard to reach or see areas. OGI tools visualize the gas leaking out of a valve, coupling, or seal. Early detection allows you to act fast, saving products and exposing fewer workers.

Regular oil pipeline inspections with infrared cameras help identify incorrectly installed parts, track how long pieces of equipment last so you can plan for repairs, and help prepare you to meet regulations, saving you time and money. OGI cameras are gaining popularity within the oil and gas industry because of their speed, accuracy, and ability to see the invisible without putting a person in contact with leaking gas. They are beginning to replace the old “sniffers” that came before them.

What tools should you use for a safe and efficient gas and oil pipeline inspection?

While Optical Gas Imaging tools are the go-to for detecting gas leaks, thermal cameras offer many other benefits for inspecting pipeline installation. Infrared cameras map out different temperatures, so they are able to monitor crude oil or gas as it moves through a pipeline. The cameras can also detect deficiencies in insulation and irregular pressure in a system. Because of this, many oil and gas industry producers turn to thermal cameras mounted on aerial drones or UAV systems to inspect and monitor long stretches of a pipeline.

Thermal infrared cameras can fly on drones, helicopters, multicopters, and smaller planes. They then send their images back to you on the ground. This allows you to inspect miles of pipeline for leaks and damages at once, saving hours of labor and transportation costs while keeping your workers out of hazardous situations.

Fast gas leak detection

Inspection with drone mounts

Excellent customer support

Additional training available

Find the solution that's right for you.

Thermal imaging for all operations in the oil and gas industry:

From life-saving gas leak prevention tools to time-saving pipeline inspection services, ICI’s thermal cameras are designed to make your upstream, midstream, and downstream operation easier, safer, and more efficient.

Multi-Sensor UAV Payloads

Handheld Thermal Cameras

Fixed Mount Thermal Cameras

Where can you use infrared cameras in the Oil and Gas Industry?

Our optical gas imaging inspectors are small and lightweight, perfect for quick detection of maintenance concerns on wellheads and platforms.

OGI cameras can monitor the transfer of the product from the source to the refining location. Pipeline inspections that utilize thermal imaging can prevent costly leaks and reactive maintenance.

As products are being refined, our cameras can properly monitor the process. In refining and petrochemical facilities, our cameras can catch any hydrocarbon-based leaks. Additionally, OGI cameras can be utilized for flare and tank monitoring.

What are the benefits of infrared cameras for the Oil and Gas industry?

Infrared cameras can enhance the safety, profitability, efficiency, and environmental protection when implemented into the Oil and Gas industry.

- Keep your workers safe from toxic emissions by using OGI tools for fast gas leak detection and contactless inspections.

- Keep workers from dangerous heights by using aerial infrared cameras for gas and oil pipeline and facility monitoring.

- Infrared cameras monitoring pressure vessels help provide accurate and real-time data that provides a safer work environment and promotes time and efficiency for projects.

- Gas flare monitoring with thermal technology grants important insights and allows for compliance with environmental and government regulations.

- Tank monitoring becomes quicker and safer with a visual representation of the tank levels.

- Cut down on fugitive emissions and ensure your oil and gas operation meets regulations by conducting complete regular inspections and continuously monitoring your oil wells, oil platforms, and more.

Experienced guidance and customized solutions

As an industry leader since 1995, ICI is here to help you find the perfect thermal imaging system for your oil and gas operation. We offer a variety of infrared cameras and OGI tools to fit your needs, wherever you are in the production chain.